Products

Contact Us

Mobile:+86-18911865558(Manager Yang)

Telephone:+86-316-5175885

E-mail:sales@jkhfseal.com

Office address: No. 1-2926, Chaichang Village East (United Airlines Building), Yongledian Town, Tongzhou District, Beijing

Production Base: No.66 Tiangao Road, Anci District, Langfang City, Hebei Province

Fan-seal - spring energy storage sealing ring

Keywords:

Classification:

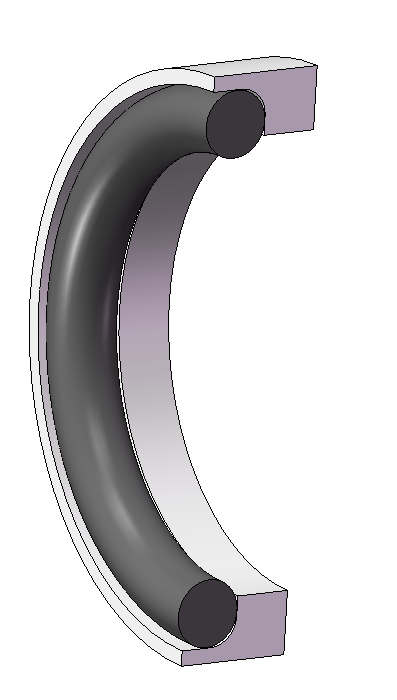

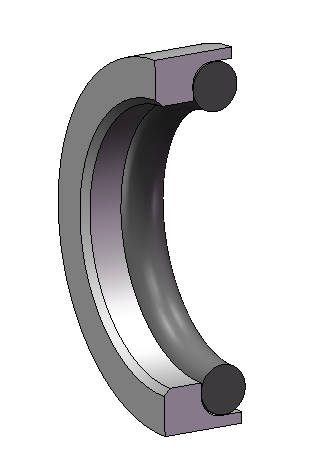

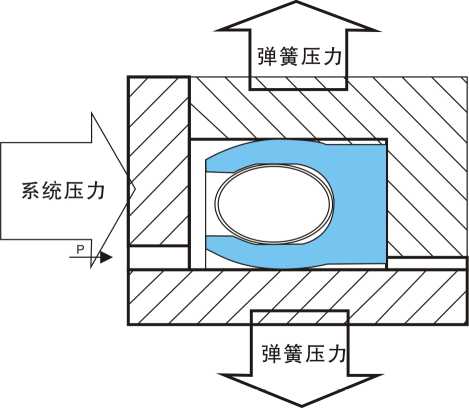

Performance and purpose

The pan plug seal is a sealing element composed of a sealing ring and a corrosion resistant spring. There are a variety of energy storage springs to choose from, and each spring has different characteristics to meet special requirements. When the sealing ring is installed in the sealing groove, the spring is pressurized to make the lip of the sealing ring close to the sealing groove, thus forming a seal. The spring provides permanent elasticity to the seal ring, and the load can meet the extremely demanding low friction requirements in dynamic applications and the high load requirements usually required for low-temperature seals, and make up for material wear and offset or eccentricity of the matched parts. By means of spring elasticity and system pressure, effective sealing can be achieved at both high and low pressures.

泛塞封是由密封环和耐腐蚀弹簧所组成的密封元件,有多种蓄能弹簧可供选择,每种弹簧各有不同的特点满足特别的要求。当密封圈装在密封沟槽内,弹簧受压,促使密封环唇边紧贴密封沟槽,由此形成密封。弹簧给密封环提供永久弹力,负荷可以达到动态应用时极端苛刻的低摩擦要求和低温密封通常需要的高负荷要求等,并弥补材料磨损及配合零件的偏移或偏心。通过弹簧弹力和系统压力,无论在高压或低压下,都可实现有效密封。

Advantage

1. Good dynamic and static seal

1、良好的动态和静态密封。

2. The coefficient of friction is small, very wear-resistant and can be sealed at speeds up to 15M/S

2、摩擦系数小,非常耐磨损,在高达15M/S的速度下能够密封。

3. High and low temperature resistance (-268℃ to +316℃) operating temperature.

3、耐高低温性能(-268℃至+316℃)的工作温度。

4. Good corrosion resistance almost universal chemical compatibility and chemical contact, no anti-elastic deformation

4、良好的耐腐蚀性能几乎通用的化学相容性与化学品接触,不发生反弹性变形。

5. Good clearance extrusion resistance

5、抗间隙挤出性能好。

6. Compact structure and easy installation

6、结构紧凑,安装简单。

Working condition

|

材料代号 Material code |

适用温度 Applicable temperature ℃ |

适用工况条件 Applicable working condition |

注意事项 Notice |

| JK-01 | -253 〜+260 |

食品、药品、低压、静密封,通用级 颜色:白色 Food, medicine, low pressure, static seal, general grade ; color: white |

高温高压易蠕变 High temperature and pressure creep |

| JK-02 | -200 〜+260 |

气动往复、旋转,低压、软金属 颜色:黑色 Pneumatic reciprocation, rotation, low pressure, soft metal ; color: black |

|

| JK-03 | -200 〜+260 |

水、蒸汽、油、化工、往复旋转、低压 颜色:黑色 Water, steam, oil, chemical, reciprocating rotation, low pressure; color: black |

高真空度慎用 Use with caution at high vacuum |

| JK-04 | -200 〜+260 |

往复、旋转,中低压、软金属 颜色:暗黄色 Reciprocating, rotating, medium and low pressure, soft metal ; color: dark yellow |

高真空度慎用 Use with caution at high vacuum |

| JK-05 | -200 〜+260 |

往复、旋转,高真空、软金属、低压 颜色:棕色 Reciprocating, rotating, high vacuum, soft metal, low pressure ; color: brown |

不适合碱性环境 Not suitable for alkaline environment |

| JK-06 | -200 〜+260 |

往复、低压、油润滑、绝缘 颜色:白色 Reciprocating, low pressure, oil lubrication, insulation; color: white |

高速时研磨软金属 Grind soft metal at high speed |

| JK-07 | -200 〜+80 |

水、食品、低温气体 颜色:白色 Water, food, low temperature gas ;color: white |

不耐高温 High temperature intolerance |

| JK-08 | -200 〜+80 |

水、低温气体、在干摩擦用途时非常耐磨 颜色:黑色 Water, low temperature gas, very wear-resistant in dry friction use; color: black |

不耐高温 High temperature intolerance |

Note: According to the specific working conditions provided by customers: temperature, pressure (or vacuum degree), speed, medium, material of grinding parts, installation conditions, etc., through testing and installation verification of specific working conditions, the company can customize sealing components that meet various harsh working conditions

注:公司可依据客户提供的具体工况要求:温度、压力(或真空度)、速度、介质、对磨件材质、安装条件等,通过试验结合具体工况条件装机验证,定制满足各种苛刻工况条件的密封元件。

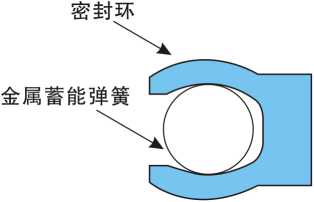

Common form of Flooding seal spring

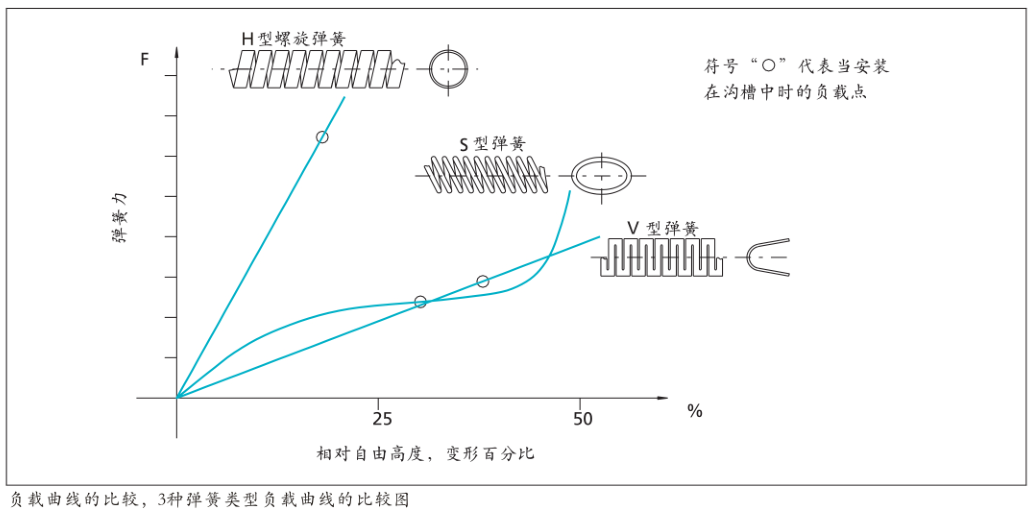

H-type spiral spring (O-type spring)

H型螺旋弹簧(O型弹簧)

H-type helical spring is a spiral spring processed with flat reed, which is widely used in various pan-plug sealing. It has a larger unit load and a shorter deformation range than other types of springs. Therefore, it is best suited for static and slow dynamic uses.

H型螺旋弹簧是用扁平簧片加工成的螺旋线弹簧,广泛用于各种泛塞封中。它比其他类型的弹簧具有更大的单位载荷和更短的变形范围。因此,它最适合用于静态和缓慢的动态用途。

V-Shape spring (U-spring)

V型弹簧(U型弹簧)

V-springs are standard springs with a moderate load and deformation range. It works like a set of "cantilevers" that unfold from an arc at the base of the spring. The shape of the spring causes the load to concentrate on the leading edge of the seal lip, giving the seal a reliable wiping action.

V型弹簧是标准弹簧,具有中等负载和变形范围。它像一组“悬臂梁”那样工作,从位于弹簧底部的弧形来展开。弹簧的形状造成负载集中在密封唇的前缘,使密封件有了可靠的擦拭作用。

S-Shape spring

S型弹簧

The S-type spring is composed of round steel wire machined into inclined coils and has a relatively constant load over a wide deformation range. This allows for precise control of friction during the working life of the seal. Its unique design ensures that the seal will not damage the spring due to excessive deformation.

S型弹簧是由圆形钢丝加工成倾斜线圈组成,在很宽的变形范围内具有相对恒定的载荷。这就允许在密封件的工作寿命期间,能够精确控制摩擦。它的独特设计使得密封件不会由于过度变形而损坏弹簧。

Spring material selection Guide

|

介质 Medium |

弹簧材料 Material of spring |

|

用于普通用途,例如油、气体、油脂、溶剂、水 空气、食品、药品、蒸汽 Used for general use, for exampleOil, gas, grease, solvent, water, air, food, medicine, |

不锈钢 Stainless steel AiSi301 |

|

用于腐蚀介质,例如酸、腐蚀剂、海水 Used for corrosive media, for exampleAcid, caustic, sea water |

Hastelloy—C-276 |

|

用于石油化工用途,例如 原油、含硫天然气 Used For petrochemical applications, such as crude oil, sour natural gas . |

Elgiloy |

Commonly used pan plug seal specification size

常用泛塞封规格尺寸

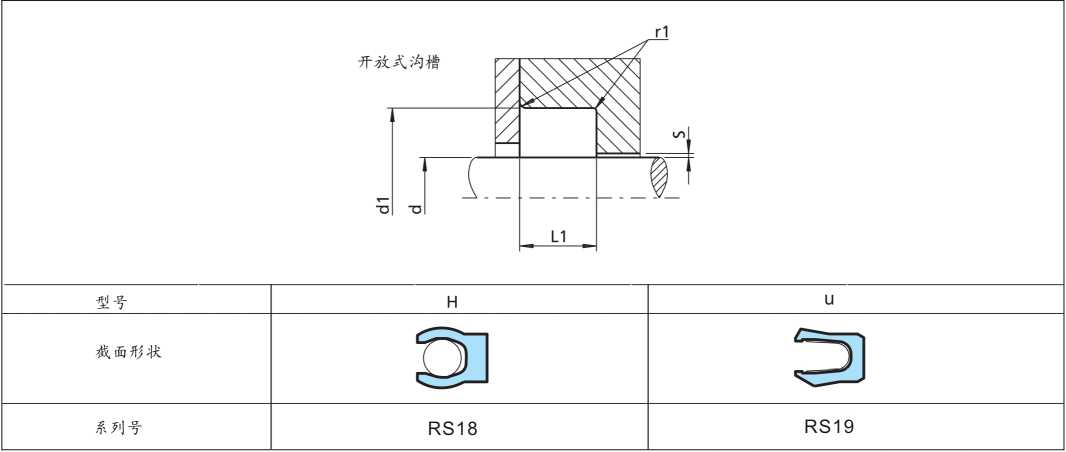

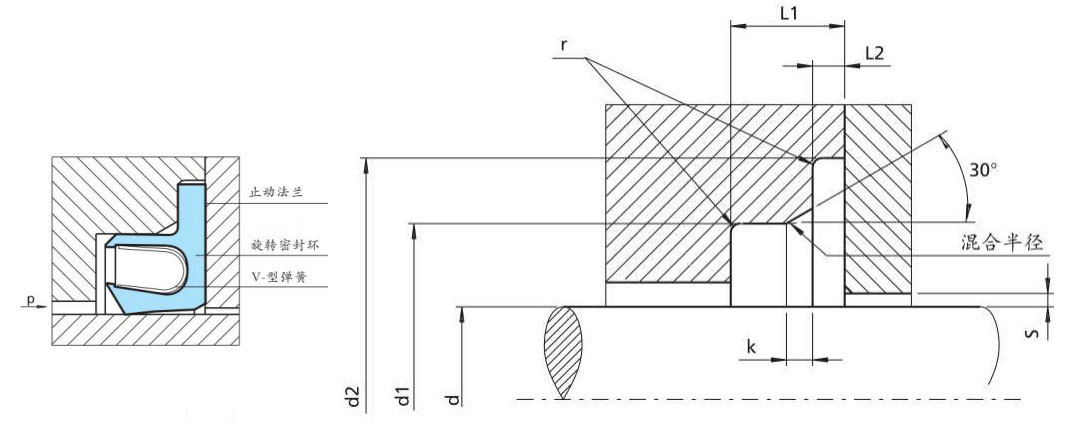

Shaft seal

Installation dimension

|

活塞杆直径 Diameter of piston rod |

沟槽 直径 Groove / Diameter |

沟槽 宽度 Groove / Width |

倒圆 Rounding |

径向间隙 Radial clearance |

|||

|

标准 范围 Standard/ Range |

d1H9 mm | L1+0.2 mm | r1 max. mm |

<2 MPa (20 bar) |

<10 MPa (100 bar) |

<20 MPa (200 bar) |

<40 MPa (400 bar) |

| 3.0 - 9.9 | d + 2.9 | 2.4 | 0.4 | 0.20 | 0.10 | 0.08 | 0.05 |

| 10.0 - 19.9 | d + 4.5 | 3.6 | 0.4 | 0.25 | 0.15 | 0.10 | 0.07 |

| 20.0 - 39.9 | d + 6.2 | 4.8 | 0.6 | 0.35 | 0.20 | 0.15 | 0.08 |

| 40.0 - 119.9 | d + 9.4 | 7.1 | 0.8 | 0.50 | 0.25 | 0.20 | 0.10 |

| 120.0 - 630.0 | d + 12.2 | 9.5 | 0.8 | 0.60 | 0.30 | 0.25 | 0.12 |

Note: The above is the common standard size specifications, if the actual size is not included, we will tailor the required sealing components for you.

注:以上为常用标准尺寸规格,若实际需要尺寸不在其中,我们将为您量身订制所需要的密封元件。

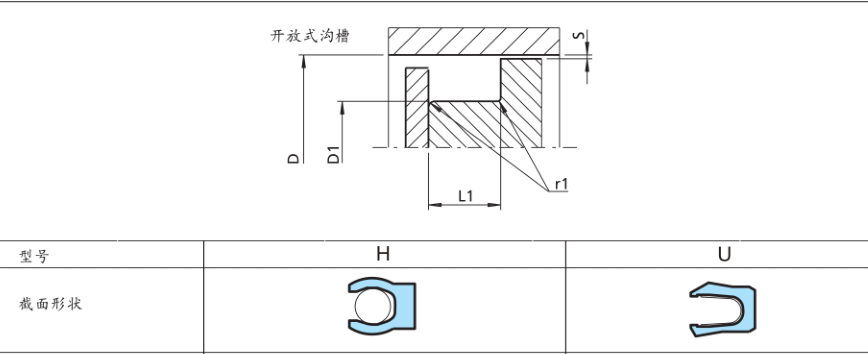

Hole seal

Installation dimension

|

活塞直径 Diameter of piston rod DH 9 mm |

沟槽 直径 Groove/Diameter |

沟槽 宽度 Groove / Width |

倒圆 Radial clearance |

径向间隙 Radial clearance |

|||

|

标准 范围 Standard/ Range |

d1H9 mm | L1+0.2 mm | r1 max. mm |

<2 MPa (20 bar) |

<10 MPa (100 bar) |

<20 MPa (200 bar) |

<40 MPa (400 bar) |

| 6.0 - 13.9 | D - 2.9 | 2.4 | 0.4 | 0.20 | 0.10 | 0.08 | 0.05 |

| 14.0 - 24.9 | D - 4.5 | 3.6 | 0.4 | 0.25 | 0.15 | 0.10 | 0.07 |

| 25.0 - 45.9 | D - 6.2 | 4.8 | 0.6 | 0.35 | 0.20 | 0.15 | 0.08 |

| 46.0 - 124.9 | D - 9.4 | 7.1 | 0.8 | 0.50 | 0.25 | 0.20 | 0.10 |

| 125.0 - 630.0 | D - 12.2 | 9.5 | 0.8 | 0.60 | 0.30 | 0.25 | 0.12 |

Note: The above is the common standard size specifications, if the actual size is not included, we will tailor the required sealing components for you.

注:以上为常用标准尺寸规格,若实际需要尺寸不在其中,我们将为您量身订制所需要的密封元件。

Rotary seal

Installation dimension

|

活塞杆直径 d f8/h9 mm |

沟槽 直径 Groove/Diameter |

沟槽 宽度 Groove/Width |

引入倒角 Bring in chamfer. |

倒圆 Rounding |

径向间隙 Radial clearance |

||||

|

标准 范围 Standard/ Range |

d1H9 mm | d2H10 mm | L1min mm | L2mm | k mm | rmax. mm | <2 MPa (20 bar) | <10 MPa (100 bar) |

<20 MPa (200 bar) |

| 5.0 - 19.9 | d + 5.0 | d + 9.0 | 3.6 | 0.85+0/-0.1 | 0.8 | 0.3 | 0.25 | 0.15 | 0.10 |

| 20.0 - 39.9 | d + 7.0 | d + 12.5 | 4.8 | 1.35+0/-0.15 | 1.1 | 0.4 | 0.35 | 0.20 | 0.15 |

| 40.0 - 399.9 | d + 10.5 | d + 17.5 | 7.1 | 1.80+0/-0.20 | 1.4 | 0.5 | 0.50 | 0.25 | 0.20 |

| 400.0 - 999.9 | d + 14.0 | d + 22.0 | 9.5 | 2.80+0/-0.20 | 1.6 | 0.5 | 0.60 | 0.30 | 0.25 |

Note: The above is the common standard size specifications, if the actual size is not included, we will tailor the required sealing components for you

注:以上为常用标准尺寸规格,若实际需要尺寸不在其中,我们将为您量身订制所需要的密封元件。

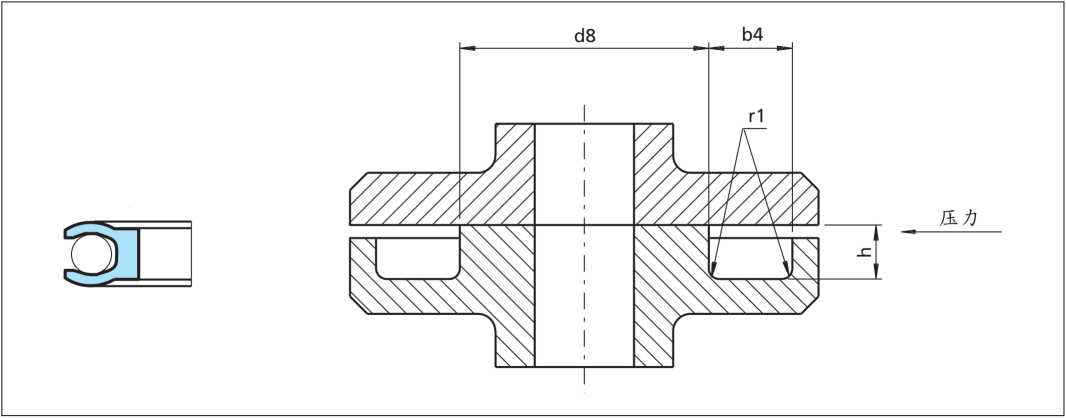

End face seal

Installation dimension

|

沟槽内侧直径 Groove inside diameter d8 H11 |

沟槽 宽度b4 mm Groove/Width b4 mm |

沟槽 深度 Groove/Depth |

倒圆 Rounding r1 mm |

|

| 推荐的范围 Recommended range | min. | h mm |

总 mm |

max. |

| 3 - 9.9 | 2.4 | 1.45 | +0.03 | 0.4 |

| 10 - 19.9 | 3.6 | 2.25 | +0.05 | 0.4 |

| 20 - 39.9 | 4.8 | 3.10 | +0.08 | 0.6 |

| 40 - 119.9 | 7.1 | 4.70 | +0.10 | 0.8 |

| 120 - 999.9 | 9.5 | 6.10 | +0.15 | 0.8 |

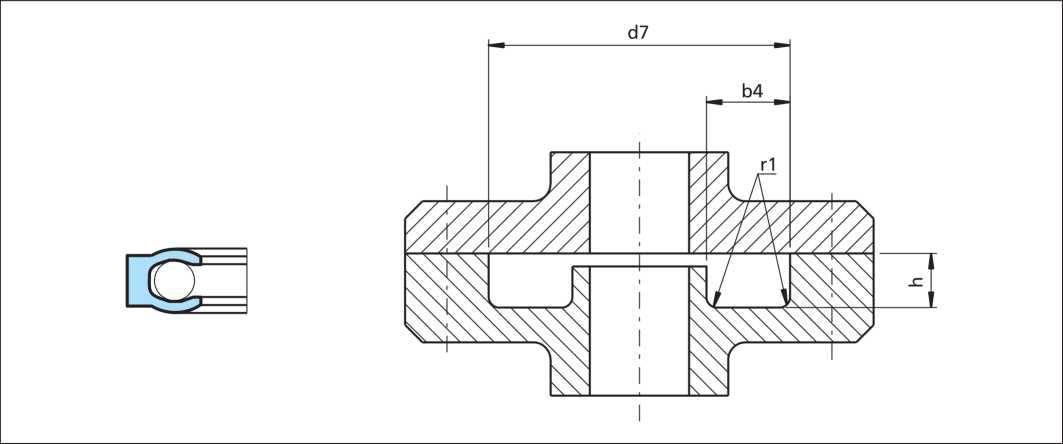

Installation Dimensions

| 沟槽外侧直径 Groove inside diameter d7 H11 |

沟槽 宽度b4 mm Groove/Width b4 mm |

沟槽 深度 Groove/depth |

倒圆 Rounding r1 mm |

|

| 推荐的范围 Recommended range | min. | h mm | Total mm | max. |

| 10 - 13.9 | 2.4 | 1.45 | +0.03 | 0.4 |

| 14 - 24.9 | 3.6 | 2.25 | +0.05 | 0.4 |

| 25 - 45.9 | 4.8 | 3.10 | +0.08 | 0.6 |

| 46 - 124.9 | 7.1 | 4.70 | +0.10 | 0.8 |

| 125 - 999.9 | 9.5 | 6.10 | +0.15 | 0.8 |

Note: The above is the common standard size specifications, if the actual size is not included, we will tailor the required sealing components for you

注:以上为常用标准尺寸规格,若实际需要尺寸不在其中,我们将为您量身订制所需要的密封元件。

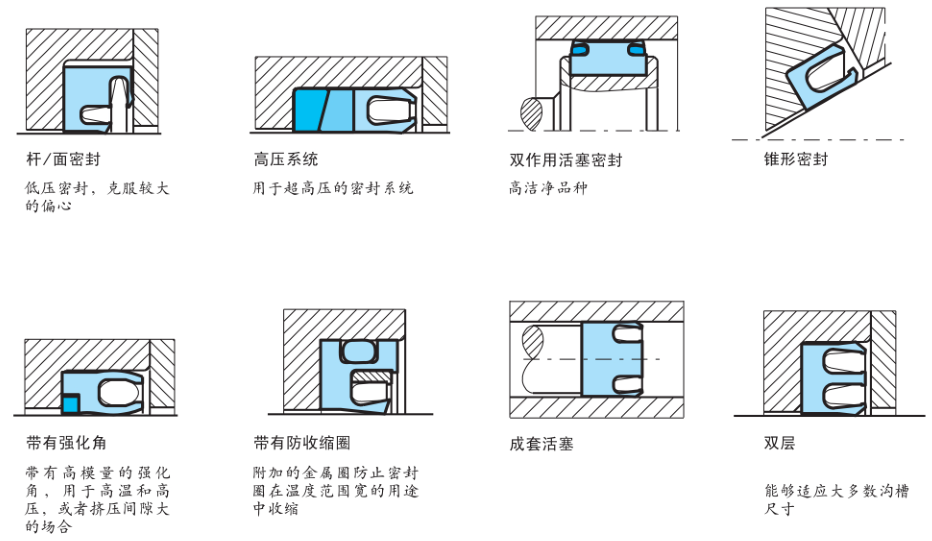

Special construction seal

Note: The above are common special structures, we can also tailor the required sealing elements according to the actual application.

注:以上为常见特殊结构,我们也可以根据实际应用情况量身订制所需要的密封元件。

Specializing in the development, production and sales of ultra-high pressure sealing components for steel pipe hydrostatic pressure test. The company is committed to the research and production of sealing components for steel pipe hydraulic testing machines, and has a strong professional R & D team and excellent after-sales service personnel. It has established cooperative relations with more than ten famous domestic hydraulic testing machine design units to design and produce various new sealing products. Standard hydrostatic pressure test requirements, stable performance, long service life, best-selling domestic and Southeast Asian markets, well received by domestic and foreign users.

Related Products

Online consultation

If you are interested in the product, please leave your contact information and we will contact you as soon as possible!

Beijing Jianke Huifeng Technology

E-mail: sales@jkhfseal.com

Production Base: No.66 Tiangao Road, Anci District, Langfang City, Hebei Province

Address: No. 1-2926, East of Chaichang Village, Yongledian Town, Tongzhou District, Beijing (Lianhang Building)

Copyright©2024 Beijing Jianke Huifeng Technology Co., Ltd