Products

Contact Us

Mobile:+86-18911865558(Manager Yang)

Telephone:+86-316-5175885

E-mail:sales@jkhfseal.com

Office address: No. 1-2926, Chaichang Village East (United Airlines Building), Yongledian Town, Tongzhou District, Beijing

Production Base: No.66 Tiangao Road, Anci District, Langfang City, Hebei Province

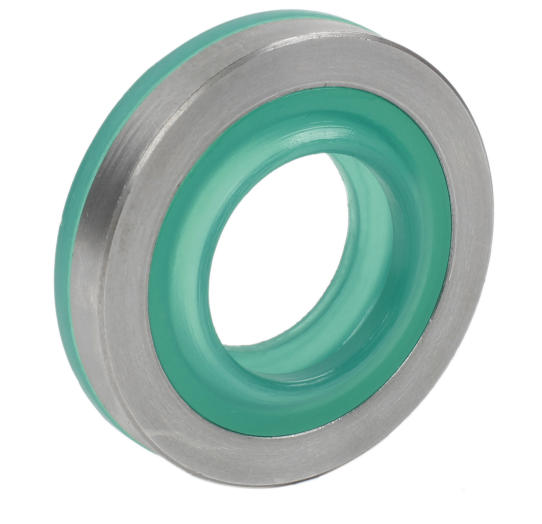

D-type ultra-high pressure large gap sealing element

Keywords:

Classification:

Performance and Purpose

The sealing component is made up of a polyurethane sealing ring and fan-shaped supporters. It is mainly used in the pressure test of steel pipe by hydro-static testing machine. In the non-working state between the sealing ring and surface of steel pipe exists gap. When hydraulic liquid is applied to the external of the sealing ring, the ring is pressed to enclose the surface of steel pipe firmly, and then the pressure testing can be performed. It is applicable to the pressure testing of casing, tubing, natural gas pipe and other steel pipe. It has also been used in leak inspection of the steel pipe, connection, welded joints and sealing for the high pressure valve.

D型超高压大间隙密封元件是由密封圈和扇形支撑块组成的密封元件。主要用于水压试验机对钢管的耐压试验。在非工作状态下,密封元件与被密封面之间有一定的间隙;工作时,密封元件受外周加压后与被密封面紧密接触实现密封,进行水压试验。本产品适用于水压试验机对套管、油管、天然气输送管道等钢管进行水压试验,也可用于钢管、管接头、焊口检漏及超高压阀门密封等。

Advantage

1. Lip Optimization: under peripheral pressure, the lip and groove surface fit more closely, and the higher the pressure, the better the lip sealing.

唇边优化,在外周受压下,是唇边与沟槽面贴合更紧密,压力越大唇边密封越好

2. The fan-shaped supporters, in the premise of increasing the strength of the sealing ring, can shrink and expand in radial direction with the sealing ring.

专业设计扇形支撑块,在增加密封圈强度的前提下,能随密封圈在径向方向收缩、胀大

Working conditions

According with API 5CT-2018、ISO11960-2014、GB/T9711-2017 etc. Such as petroleum and natural gas industries——Steel pipes for use as casing or tubing for wells; GB/T8163-2018 seamless steel tubes; GB/T3091-2015 welded steel pipes, and other standard hydraulic testing conditions.

符合API 5CT-2018、ISO11960-2014、GB/T9711-2017等石油天然气工业——油气井套管或油管用钢管;GB/T8163-2018无缝钢管;GB/T3091-2015焊接钢管等标准水压试验条件

Working pressure: ≤ 120 MP a

Working temperature: -20 to +80℃

Working medium: water, emulsion, hydraulic oil

Material: Polyurethane

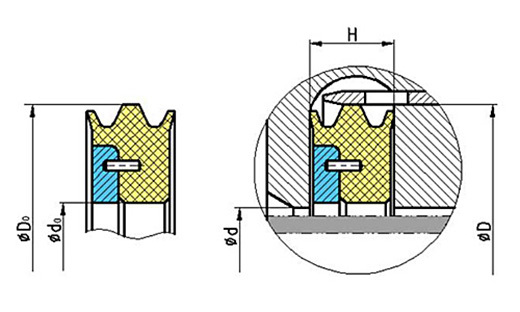

| 序号 No. |

规格型号 Type |

钢管规格 Pipe size |

密封圈尺寸 Sealing dimension |

沟槽尺寸 Groove dimension |

订货号 Order No. |

|||

| d0 | D0 | d | D | H+0.2 | ||||

| 1 | D32-40 | 1-1/4" | 38 | 134 | 35 | 133 | 40 | D221 |

| 2 | D32-33.5 | 1-1/4" | 48 | 168 | 38 | 167 | 33.5 | D301 |

| 3 | D42-33.5 | 1.65" | 58 | 169 | 49 | 168 | 33.5 | D319 |

| 4 | D48-33.5 | 1.9" | 64 | 169 | 55 | 168 | 33.5 | D303 |

| 5 | D60.3-40 | 2-3/8" | 76 | 166 | 68 | 165 | 40 | D222 |

| 6 | D60.3-33.5 | 2-3/8" | 76 | 169 | 68 | 168 | 33.5 | D304 |

| 7 | D73-40 | 2-7/8" | 91 | 188 | 80 | 187 | 40 | D224 |

| 8 | D73-33.5 | 2-7/8" | 89 | 182 | 80 | 180 | 33.5 | D305A |

| 9 | D88.9-40 | 3-1/2" | 108 | 203 | 97 | 201 | 40 | D228 |

| 10 | D88.9-34.5 | 3-1/2" | 106 | 195 | 97 | 193 | 34.5 | D306 |

| 11 | D101.6-40 | 4" | 128 | 222 | 112 | 220 | 40 | D230 |

| 12 | D101.6-33.5 | 4" | 120 | 208 | 112 | 206 | 33.5 | D308 |

| 13 | D108-40 | 4-1/4" | 122 | 218 | 116 | 216 | 40 | D229 |

| 14 | D114.3-40 | 4-1/2" | 141 | 245 | 124 | 243 | 40 | D231 |

| 15 | D114.3-33.5 | 4-1/2" | 128 | 208 | 122 | 206 | 33.5 | D309 |

| 16 | D114.3-40 | 4-1/2" | 130 | 220 | 124 | 218 | 40 | D502 |

| 17 | D127-40.5 | 5" | 150 | 248 | 137 | 246 | 40.5 | D202 |

| 18 | D127-39.5 | 5" | 145 | 238 | 137 | 236 | 39.5 | D310 |

| 19 | D133.35-40.5 | 5-1/4" | 150 | 248 | 143 | 246 | 40.5 | D202(1) |

| 20 | D133.35-40 | 5-1/4" | 151 | 238 | 143 | 236 | 40 | D511 |

| 21 | D139.7-40.5 | 5-1/2" | 163 | 261 | 150 | 259 | 40.5 | D203 |

| 22 | D139.7-40 | 5-1/2" | 165 | 260 | 150 | 258 | 40 | D233 |

| 23 | D139.7-33.5 | 5-1/2" | 156.4 | 231.3 | 150 | 229.5 | 33.5 | D311 |

| 24 | D147.32-40.5 | 5-4/5" | 163 | 261 | 157 | 259 | 40.5 | D203(2) |

| 25 | D147.32-34.5 | 5-4/5" | 169 | 247 | 157 | 245 | 34.5 | D312(4) |

| 26 | D152-40 | 6" | 179 | 283 | 163 | 281 | 40 | D204 |

| 27 | D153.7-40 | 6.05" | 172 | 268 | 164 | 266 | 40 | D238 |

| 28 | D153.7-40 | 6.05" | 173 | 272.5 | 164 | 270.5 | 40 | D239 |

| 29 | D159-40 | 6-1/4" | 185 | 283 | 170 | 281 | 40 | D205 |

| 30 | D160.02-40 | 6.3" | 179 | 283 | 170 | 281 | 40 | D204(1) |

| 31 | D168.3-40 | 6-5/8" | 181 | 284 | 176 | 282 | 40 | D241A |

| 32 | D168.3-40 | 6-5/8" | 183 | 280 | 177 | 278 | 40 | D242 |

| 33 | D177.8-40.5 | 7" | 194 | 292 | 188 | 290 | 40.5 | D207 |

| 34 | D177.8-40 | 7" | 202 | 306 | 188 | 304 | 40 | D245 |

| 35 | D184-40 | 7-1/4" | 201 | 292 | 194 | 290 | 40 | D216 |

| 36 | D187.7-40 | 7.39" | 205 | 311 | 198 | 309 | 40 | D279 |

| 37 | D187.7-40 | 7.39" | 202 | 298 | 196 | 296 | 40 | D244 |

| 38 | D193.7-40 | 7-5/8" | 214 | 311 | 205 | 309 | 40 | D208 |

| 39 | D193.7-40 | 7-5/8" | 210 | 312 | 204 | 310 | 40 | D246 |

| 40 | D194.5-40 | 7.656" | 214 | 311 | 205 | 309 | 40 | D208(1) |

| 41 | D197-40 | 7-3/4" | 226 | 334.5 | 208 | 332.5 | 40 | D285 |

| 42 | D200.03-36 | 7-7/8" | 210 | 282 | 206 | 280 | 36 | D316A |

| 43 | D200.03-40 | 7-7/8" | 214 | 311 | 208 | 309 | 40 | D208(3) |

| 44 | D200.03-40 | 7-7/8" | 210 | 312 | 206 | 310 | 40 | D246(1) |

| 45 | D203-39.5 | 8" | 225 | 320 | 214 | 318 | 39.5 | D209 |

| 46 | D219.1-40.5 | 8-5/8" | 233 | 331 | 228 | 329 | 40.5 | D210 |

| 47 | D219.1-40 | 8-5/8" | 231 | 336 | 226 | 334 | 40 | D249 |

| 48 | D232-39.5 | 9-1/8" | 248 | 340 | 240 | 338 | 39.5 | D211 |

| 49 | D240-40 | 9.45" | 261 | 357 | 250 | 355 | 40 | D261 |

| 50 | D244.5B-40 | 9-5/8" | 259.5 | 355.5 | 254 | 353.5 | 40 | D253 |

| 51 | D244.5-43.5 | 9-5/8" | 269 | 365 | 254 | 363 | 43.5 | D254 |

| 52 | D269.9-40 | 10-5/8" | 285 | 384 | 279 | 382 | 40 | D217 |

| 53 | D273.1-43.5 | 10-3/4" | 300 | 396 | 284 | 394 | 43.5 | D255 |

| 54 | D273.1-40 | 10-3/4" | 287 | 389 | 282 | 387 | 40 | D213 |

| 55 | D273.1-40 | 10-3/4" | 288 | 388 | 282 | 386 | 40 | D258 |

| 56 | D298.5-40 | 11-3/4" | 313 | 409 | 307 | 407 | 40 | D259 |

| 57 | D323.9-40 | 12-3/4" | 349.5 | 445.5 | 335 | 443.5 | 40 | D260 |

| 58 | D339.7-40 | 13-3/8" | 360.5 | 450.5 | 352 | 448.5 | 40 | D263 |

| 59 | D346.08-40 | 13-5/8" | 366 | 465 | 358 | 463 | 40 | D296 |

| 60 | D355.6-40 | 14" | 378 | 468 | 368 | 466 | 40 | D266 |

| 61 | D365-40 | 14-3/8" | 386 | 488 | 377 | 486 | 40 | D299 |

| 62 | D371-40 | 14.6" | 391 | 500 | 383 | 498 | 40 | D286 |

| 63 | D377-40 | 14.843" | 410 | 500 | 390 | 498 | 40 | D268 |

| 64 | D377-40 | 14.843" | 402 | 500 | 390 | 498 | 40 | D280 |

| 65 | D394-46 | 15.51" | 413 | 536 | 406 | 534 | 46 | D287 |

| 66 | D406.4-46 | 16" | 424.5 | 536 | 418 | 534 | 46 | D269A |

| 67 | D426-46 | 16.772" | 450 | 564 | 440 | 562 | 46 | D270 |

| 68 | D445-46 | 17.52" | 468 | 600 | 458 | 598 | 46 | D501 |

| 69 | D457-46 | 18" | 480 | 600 | 470 | 598 | 46 | D271 |

| 70 | D465-46 | 18.307" | 496 | 620 | 480 | 618 | 46 | D272 |

| 71 | D473-46 | 18-5/8" | 500 | 634 | 488 | 632 | 46 | D290 |

| 72 | D480-46 | 18.898" | 506 | 634 | 495 | 632 | 46 | D273 |

| 73 | D508B-46 | 20" | 528 | 671 | 521 | 669 | 46 | D274B |

| 74 | D530-46 | 20.866" | 556 | 696 | 545 | 694 | 46 | D275 |

| 75 | D559-46 | 22" | 584 | 730 | 574 | 728 | 46 | D276 |

| 76 | D609-46 | 24" | 632 | 795 | 624 | 793 | 46 | D277 |

| 77 | D630-46 | 24.803" | 662 | 830 | 648 | 828 | 46 | D278 |

| 78 | D660-51 | 26" | 682 | 867 | 675 | 865 | 51 | D288 |

| 79 | D660-51 | 26" | 683 | 830 | 675 | 828 | 51 | D288B |

| 80 | D711-51 | 28" | 733 | 932 | 726 | 930 | 51 | D289 |

| 81 | D762-51 | 30" | 785 | 1002 | 778 | 1000 | 51 | D292 |

Specializing in the development, production and sales of ultra-high pressure sealing components for steel pipe hydrostatic pressure test. The company is committed to the research and production of sealing components for steel pipe hydraulic testing machines, and has a strong professional R & D team and excellent after-sales service personnel. It has established cooperative relations with more than ten famous domestic hydraulic testing machine design units to design and produce various new sealing products. Standard hydrostatic pressure test requirements, stable performance, long service life, best-selling domestic and Southeast Asian markets, well received by domestic and foreign users.

Previous

C-type ultra-high pressure ultra-large gap sealing element

Related Products

Online consultation

If you are interested in the product, please leave your contact information and we will contact you as soon as possible!

Beijing Jianke Huifeng Technology

E-mail: sales@jkhfseal.com

Production Base: No.66 Tiangao Road, Anci District, Langfang City, Hebei Province

Address: No. 1-2926, East of Chaichang Village, Yongledian Town, Tongzhou District, Beijing (Lianhang Building)

Copyright©2024 Beijing Jianke Huifeng Technology Co., Ltd